Pickering emulsion

A Pickering emulsion is an emulsion that is stabilized by solid particles (for example colloidal silica) which adsorb onto the interface between the two phases. This type of emulsion was named after S.U. Pickering, who described the phenomenon in 1907, although the effect was first recognized by Walter Ramsden in 1903.[1][2]

If oil and water are mixed and small oil droplets are formed and dispersed throughout the water, eventually the droplets will coalesce to decrease the amount of energy in the system. However, if solid particles are added to the mixture, they will bind to the surface of the interface and prevent the droplets from coalescing thus causing the emulsion to be more stable.

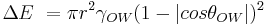

Properties such as hydrophobicity, shape, and size of the particle can have an effect on the stability of the emulsion. The particle’s contact angle to the surface of the droplet is a characteristic of the hydrophobicity. If the contact angle of the particle to the interface is low, the particle will be mostly wetted by the droplet and therefore will not be likely to prevent coalescence of the droplets. Particles that are partially hydrophobic (i.e. contact angle of approximately 90°) are better stabilizers because they are partially wettable by both liquids and therefore bind better to the surface of the droplets. The stabilization energy is given by

where r is the particle radius,  is the interfacial tension, and

is the interfacial tension, and  is the contact angle. When the contact angle is approximately 90°, the energy required to stabilize the system is at its minimum.[3]

is the contact angle. When the contact angle is approximately 90°, the energy required to stabilize the system is at its minimum.[3]

Generally the phase that preferentially wets the particle will be the continuous phase in the emulsion system.

Additionally, it has been demonstrated that the stability of the Pickering emulsions can be improved by the utilization of amphiphilic particles so-called "Janus Particles", due to the higher adsorption energy of the particles at the liquid-liquid interface.[4]

Homogenised milk is an example of a Pickering-stabilized emulsion. Casein (protein) units are adsorbed at the surface of milk fat globules and act as a surfactant. The casein replaces the milkfat globule membrane (MFGM), which is damaged during homogenisation.

Recently, using latex particles for Pickering stabilization and then fusing these particles to form a permeable shell, a new form of particle called a colloidosome, has been developed for encapsulation.[5]

See also

References

- ^ Emulsions. doi:10.1039/CT9079102001. S.U. Pickering, J. Chem. Soc. 91 (1907) 2001

- ^ Separation of Solids in the Surface-layers of Solutions and 'Suspensions'. doi:10.1098/rspl.1903.0034. W. Ramsden, Proc. R. Soc. London 72 (1903) 156

- ^ Velikov,K.P., Velev, O.D. "Stabilization of thin films, foams, emulsions and bifluid gels with surface-active solid particles" In Colloid Stability and Application in Pharmacy, T. F. Tadros, Ed., Wiley-VCH Publ. Weinheim, 2007, pp. 277-306

- ^ Binks B. P. and Fletcher P. D. I., Particles Adsorbed at the Oil-Water Interface: A Theoretical Comparison between Spheres of Uniform Wettability and “Janus” Particles, Langmuir, 17, 4708-4710, 2001.

- ^ Dinsmore AD, Hsu MF, Nikolaides MG, Marquez M, Bausch AR, Weitz DA, Colloidosomes: Selectively permeable capsules composed of colloidal particles SCIENCE 298:1006-1009, 2002